If you are thinking about designing a custom aluminum extruded part, we are here to help you! The Design Guide and Checklist will offer you information to get started. Feel free to give us a call. Our extrusion engineers have decades of experience that can save you time and money. We’ll help you get it right from the start.

If the part you need is a standard shape, we will be glad to help you look through our Standard Dies.

Brite Dip Up to16'

Acid Etch Solid profiles up to20'

Acid Etch Hollow profiles up to18'

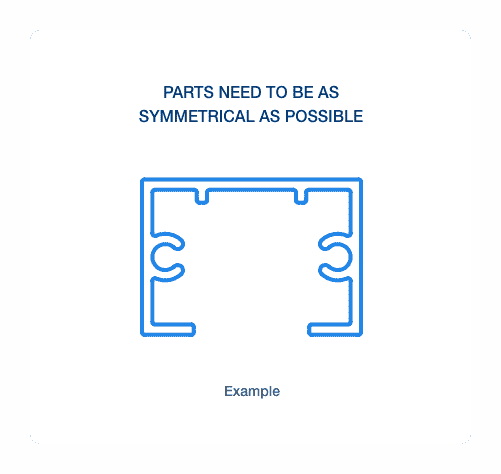

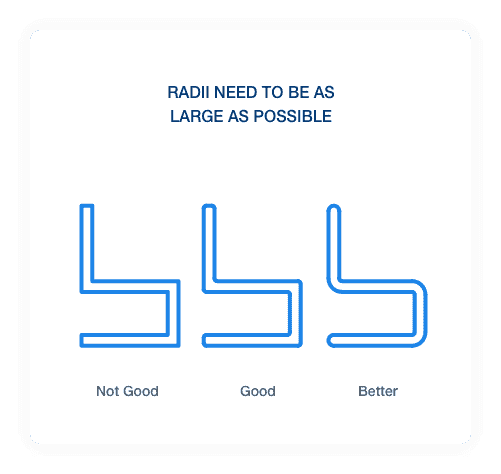

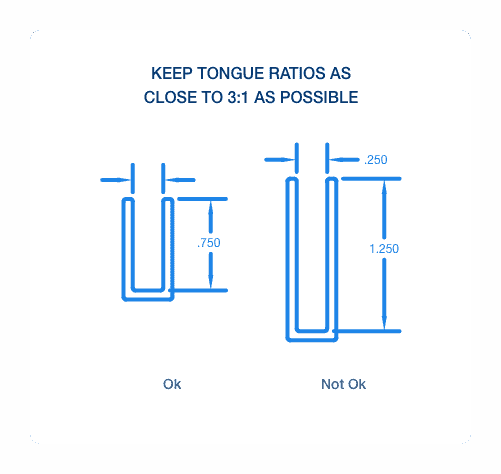

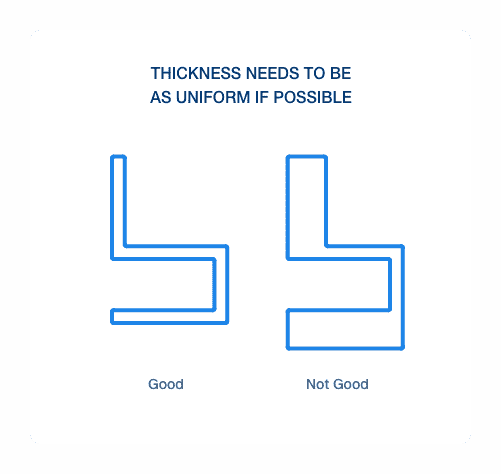

For the most cost-effective, functional, and attractive part, your design should be as production-friendly as possible.

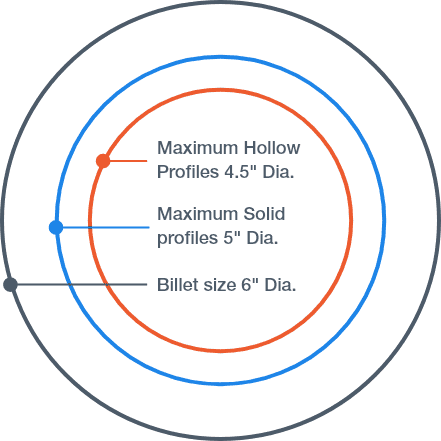

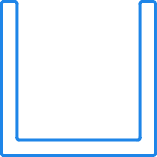

Use solid dies wherever possible. They are easier to extrude; reduce die cost; takes 2 weeks to make a solid die.

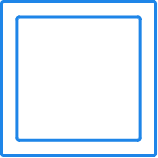

An extruded shape which completely encloses a void. Harder to push, costs more to construct a hollow die; takes 3 weeks

Often you can put a screw boss in your design to save die costs. A fully encapsulated hole qualifies as a hollow die. By using a screw boss design, you get the functionality of the hole, less metal required in the extrusion, and a less expensive solid die.to make a hollow die.

- Description or drawing of part, with part name and number

- Tolerances required. If special tolerances are required for the part, be sure to discuss before making the die.

- Fits and assemblies. Mating parts are required to design a part that will produce a good fit.