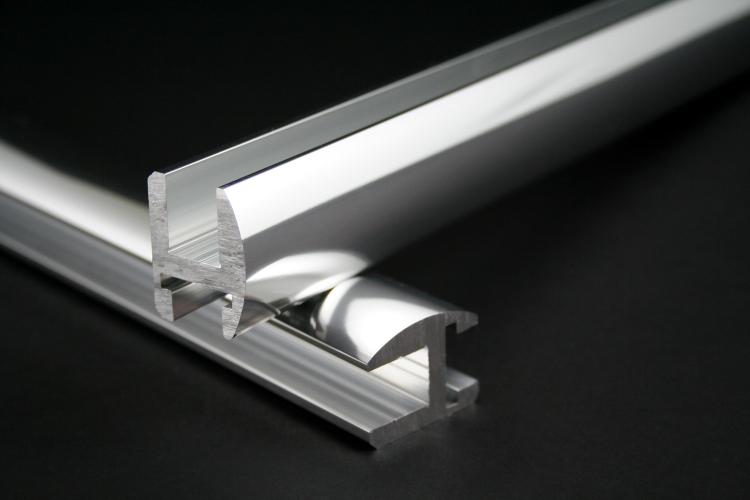

Anodizing

Anodizing is an electrochemical process that forms a durable oxide coating on aluminum. The anodic coating is part of the metal but has a porous structure that allows secondary infusion, such as coloring.

Benefits of an anodized finish include

- Increased Durability

- Pleasing appearance

- No Chipping, Peeling, or Flaking

- No Fingerprints

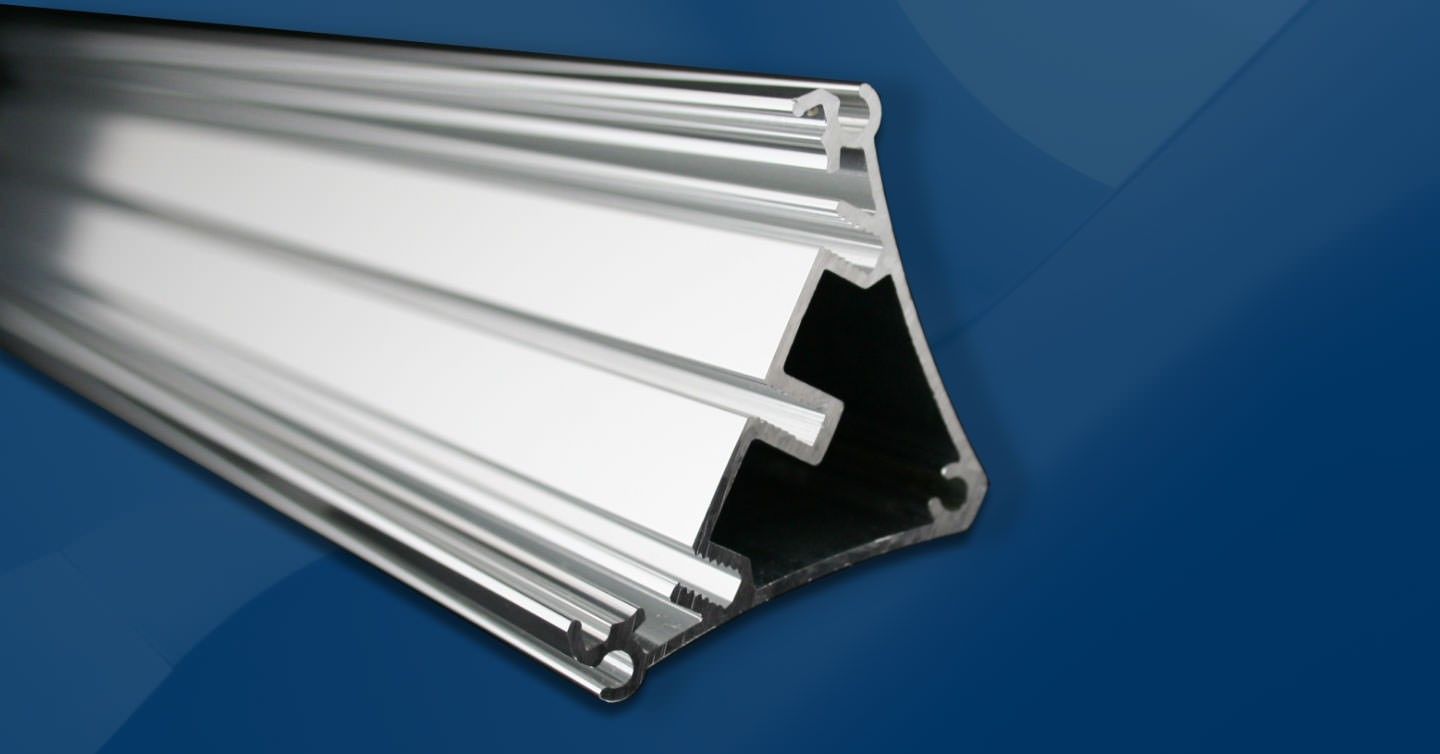

Brite Dip Anodizing

200 R5

Silver

Mechanically Buffed, Brushed, or Mill Brite

203 R5

Gold

Mechanically Buffed, Brushed, or Mill Brite

215 R5

Black

Mechanically Buffed, Brushed, or Mill Brite

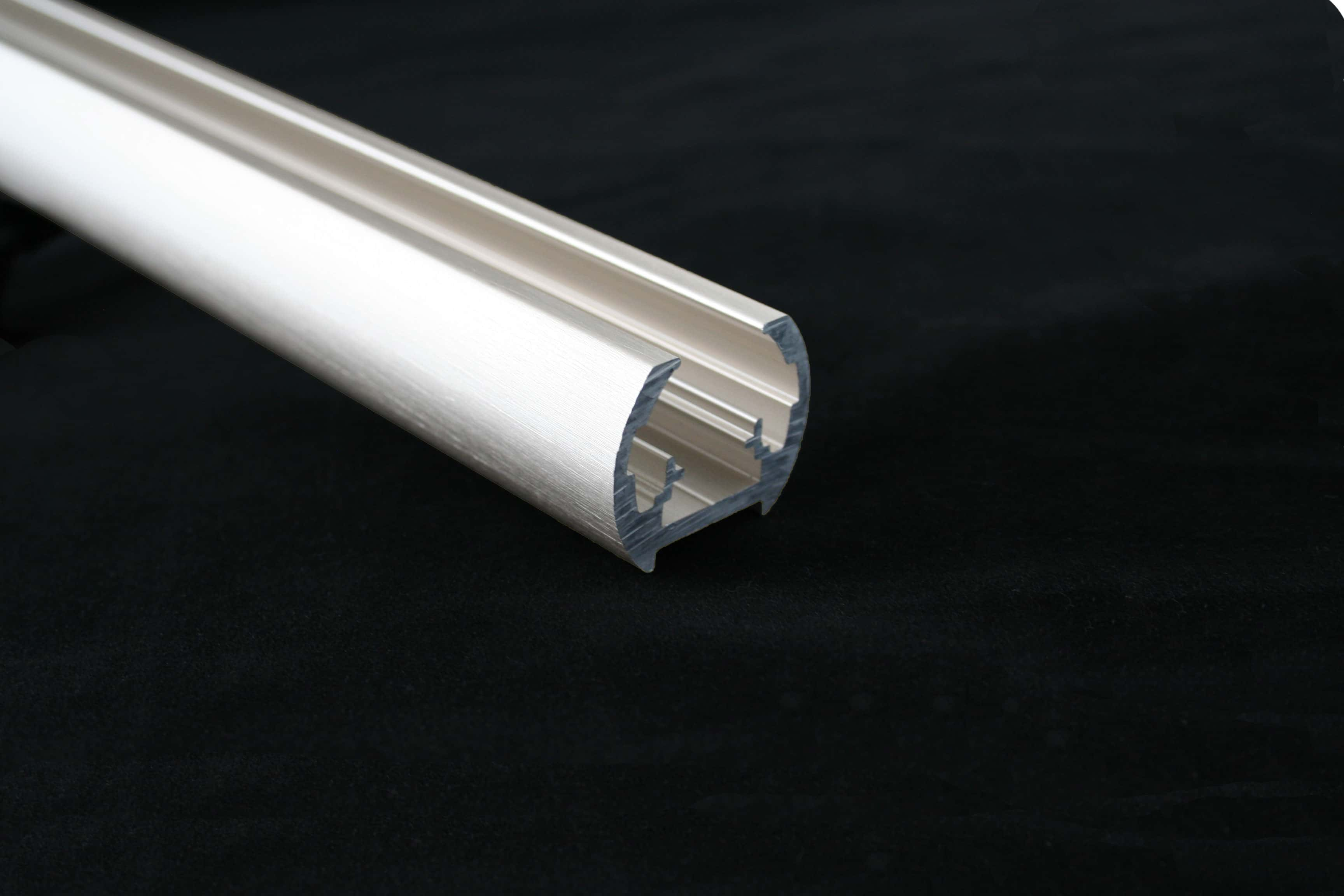

Brushed Nickel Anodizing

214 R5

Nickel

Mechanically Brushed

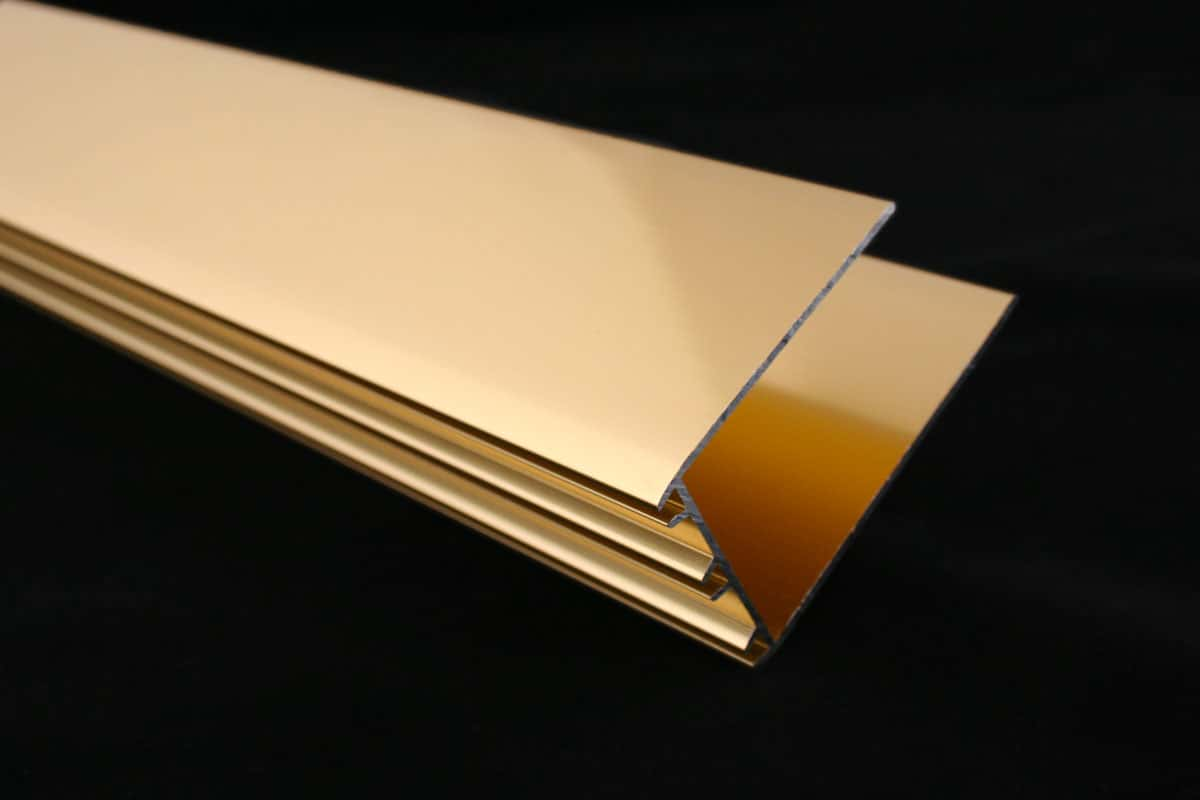

Acid Etch Anodizing

200 R1

Silver Matte Finish

Environmentally friendly

203 R1

Gold Matte Finish

Environmentally friendly

215 R1

Black Matte Finish

Environmentally friendly

Anodize Code Designations (Aluminum Association Standards)

| Brite Dip | 200 R5 Minimum coating thickness | .15/mils |

| Acid Etch | 200 R1 Minimum Coating thickness | .15/mils |

| Brushed Nickel | 214 R5 Minimum Coating thickness | .70/mils |

| Black Anodizing | 215 R5 Brite Dip or Etch Minimum Coating thickness | .90/mils |

Racking Information

Briteline has many racking options. It is important to discuss your precise requirements for “good metal” and rack mark areas with your Briteline Sales Representative.