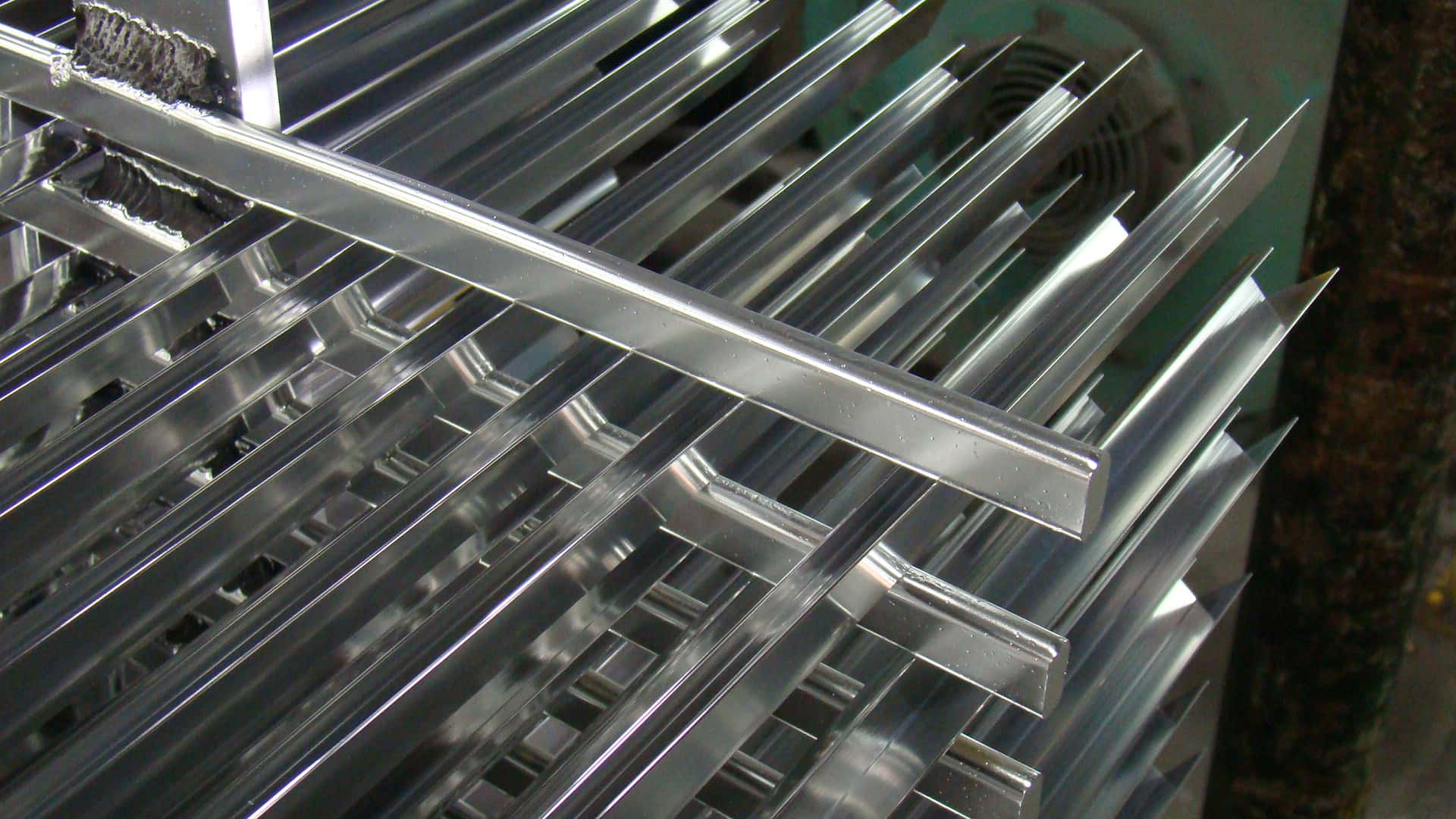

Racking Your Aluminum Extrusions

Before anodizing, your extrusions must be carefully placed to make good contact with the rack. This provides good conductivity for the required electrical current and safely carries the racked extrusions through the anodizing process.

Briteline uses two main types of racking methods:

Twist Racking

Stack Racking

The size and shape of your profile determines how it can be racked. It is important to define what is acceptable for rack marks for each profile during the quoting process.

Large Shapes

Larger shapes can be racked close to the end.

Lightweight Shapes

Lightweight shapes must be racked further in to keep them from sagging on the rack.